Services

The shop is a source for custom part prototyping and machine part problem solving. Its services include machining, fabricating, welding, design and precise measurement of mechanical parts and assemblies.

Contact Us

Email us at phys-machine@divms.uiowa.edu.

Location: 116 Van Allen Hall

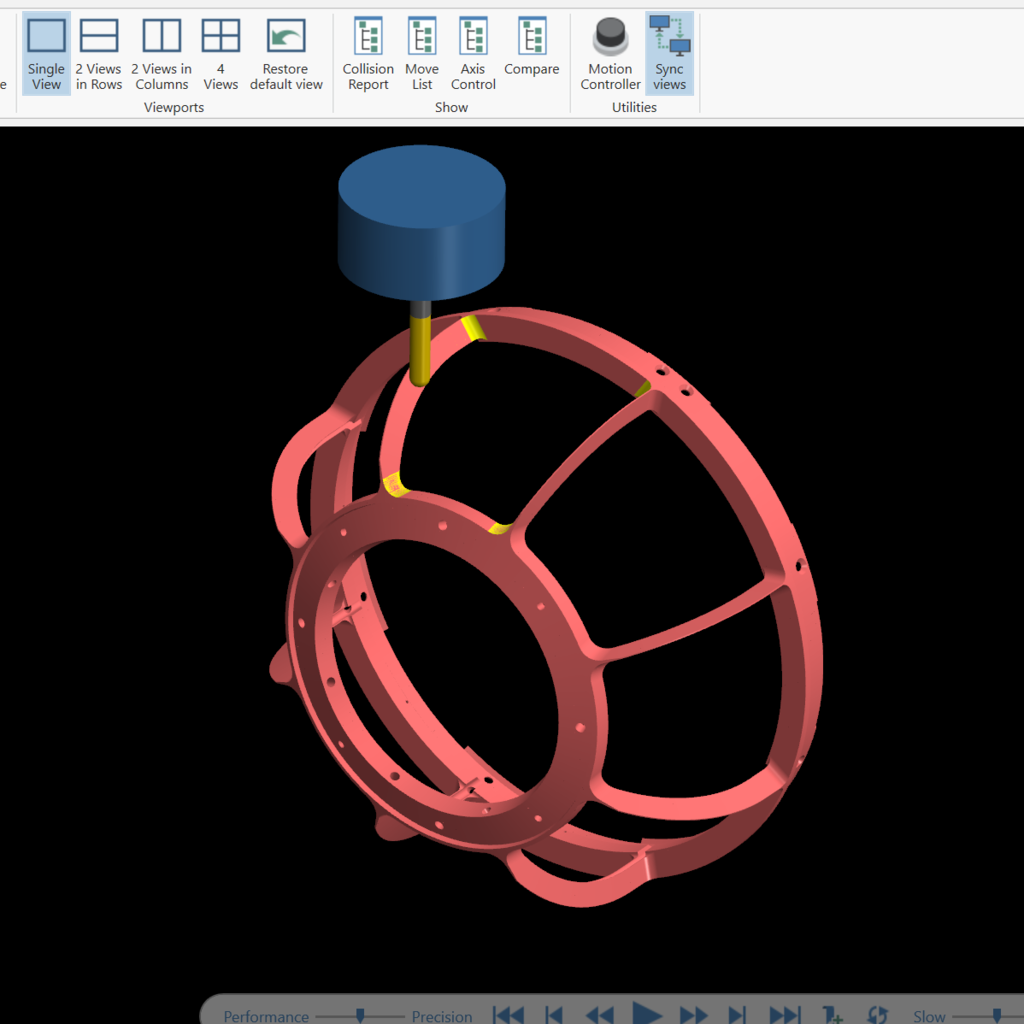

CAD/CAM Design

AutoCAD/CAM, Inventor and MasterCAM are used to design parts, assemblies, mechanical drawings, and create programs to control the CNC machines. CAD is also used to view most parts models or drawings that were made in a different CAD program.

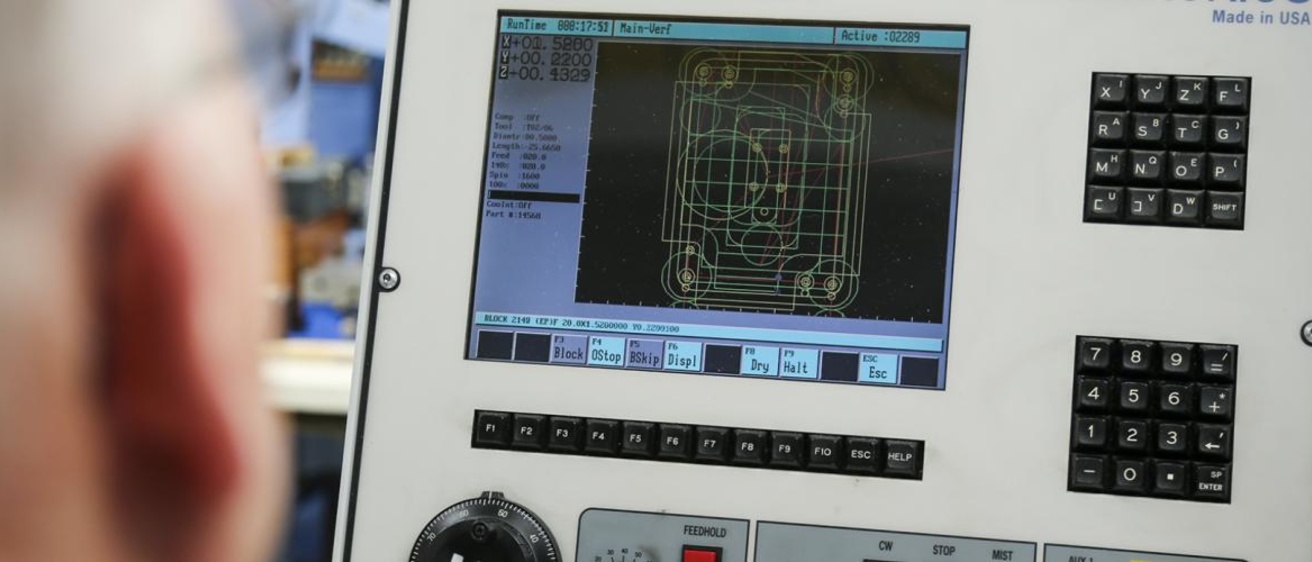

Machining

Computer numerical control (CNC) machining is a method for automating control of machine tools using software embedded in a microcomputer attached to the tool.

Electrical Discharge Machining (EDM) is a non-traditional method in which material is removed from a workpiece using thermal energy. Much like processes such as laser cutting, EDM does not need mechanical force in the removal process.

Our equipment has 4th and 5th axis machining capabilities.

Welding/Fabrication

- Brazing/soldering

- TIG/MIG welding

- Sheet metal bending and forming

- Fixture Design

- Heat treating of materials

Machine Name | Function | Materials | Uses | Dimensions |

|---|---|---|---|---|

Haas VF-2YT

| 3/4/5 axis Vertical Machining | Stainless steel, mild steel, cast iron, alloy steel, carbon steel, bronze, brass, copper, titanium, aluminum, composites, and plastics. | A manufacturing process where the material is removed, using rotating cutting tools, from a workpiece to reach a desired final shape and size | Travels: X=30”, Y=20”, Z=20” |

| Haas VF-2YT 3 Axis Vertical Machining Center Fitted with TR160 4th/5th Axis Rotary Attachment | 3/4/5 axis Vertical Machining | Stainless steel, mild steel, cast iron, alloy steel, carbon steel, bronze, brass, copper, titanium, aluminum, composites, and plastics. | A manufacturing process where the material is removed, using rotating cutting tools, from a workpiece to reach a desired final shape and size. | Travels: X=30”, Y=20”, Z=20” |

Milltronics MB-20 Partner

| 3 axis Vertical Machining | Stainless steel, mild steel, cast iron, alloy steel, carbon steel, bronze, brass, copper, titanium, aluminum, composites, and plastics. | A manufacturing process where the material is removed, using rotating cutting tools, from a workpiece to reach a desired final shape and size | Travels: X=40”, Y=20”, Z=24” |

| Aristech CNC 350 Sinker Electrical Discharge Machine (EDM) | 3 axis Vertical Electrical Discharge Machining | Virtually any electrically conductive material | A manufacturing process where the material is removed using premade tools/electrodes that electrically erode a workpiece to reach a desired final shape and size | Travels: X=15.748”, Y=11.811”, Z1=7.086”, Z2=8.267” |

| Milltronics ML-20 Partner 2 Axis Turning Machine (Lathe) | 2 axis Horizontal Turning (Lathe Turning) | Stainless steel, mild steel, cast iron, alloy steel, carbon steel, bronze, brass, copper, titanium, aluminum, composites, and plastics. | A manufacturing process where material is removed, using fixed cutting tools, from a rotating workpiece to reach a desired final shape and size | Travels: X=40”, Y=20”, Z=24” |

| Haas TM-2P 3 Axis Vertical Machining Center | 3 axis Vertical Machining | Stainless steel, mild steel, cast iron, alloy steel, carbon steel, bronze, brass, copper, titanium, aluminum, composites, and plastics. | A manufacturing process where the material is removed, using rotating cutting tools, from a workpiece to reach a desired final shape and size | Travels: X=40”, Y=16”, Z=16” |

| Milltronics MB-30 Partner 3 Axis Quill Head Bed Milling Machine with Optional 4 Axis Rotary Attachment | 3/4 axis Vertical Machining | Stainless steel, mild steel, cast iron, alloy steel, carbon steel, bronze, brass, copper, titanium, aluminum, composites, and plastics | A manufacturing process where the material is removed, using rotating cutting tools, from a workpiece to reach a desired final shape and size | Travels: X=60”, Y=30”, Z=28” |

UI ProtoLabs

The machine shop collaborates with UI Protostudios a state-of-the-art, rapid-prototyping facility located at MERGE coworking space in downtown Iowa City. Focusing on biomedical and electronics prototyping, Protostudios helps Iowa entrepreneurs create prototypes and advance their research or business.

- CNC laser cutting of most woods and plastics

- CNC laser engraving of most woods, plastics, and metals

- CNC waterjet cutting and engraving

- 3D Printing

Customers

The shop supports many University of Iowa Department of Physics and Astronomy projects, including space physics, high energy physics, plasma physics, and astronomy, but also collaborates with other departments across campus. External clients include:

- Penn State University

- University of California, Berkeley

- CERN

- JPL

- NASA

- Millennium Space Systems

Contact us for work requests/inquiries

Please include a title and detailed description of your project along with an MFK (on-campus clients) and any documentation; .dxf/.stp files are preferred. Also, include your time frame for the project. This request will generate a ticket, which will ensure the job gets scheduled and completed.

Alternatively, the Machine Shop maintains an open-door policy, and you can go in person to request the job. Machine Shop staff will create the ticket for you.

Rates: $86/hour for University of Iowa clients; $100/hour for external clients

Machine Shop staff

Matthew C. Miller